Quality Control

- Home

- Quality Control

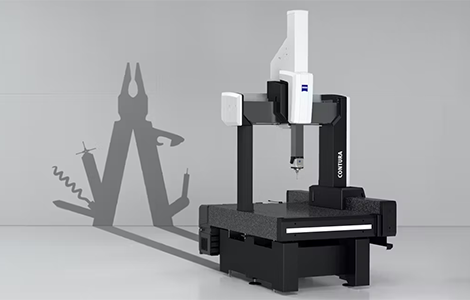

At Cimmaster, a strong commitment to product quality and precision is evident through their implementation of an internal Coordinate Measuring Machine (CMM) certification process. With an unwavering dedication to delivering products of the highest standard, Cimmaster has established an in-house CMM certification program that ensures the accuracy and reliability of its offerings. By conducting rigorous evaluations using their own state-of-the-art CMM equipment, Cimmaster’s skilled technicians meticulously inspect and measure various aspects of their products to verify compliance with stringent quality benchmarks. This internal certification not only demonstrates the company’s emphasis on maintaining consistent excellence but also affirms its capability to meet and exceed industry-specific requirements.

Why Choose Our Manual Machining Services

The internal CMM certification process at Cimmaster represents a comprehensive approach to quality assurance that encompasses both design and manufacturing phases. Beginning with initial product designs, the company’s engineers work closely with the CMM team to establish precise dimensional tolerances and measurement parameters. This collaborative effort ensures that products are not only conceived with quality in mind but are also readily certifiable through the CMM assessment. As products move through the manufacturing process, they undergo meticulous scrutiny at critical stages to validate their conformity to predefined specifications. The use of the internal CMM certification not only underlines Cimmaster’s commitment to producing exceptional products but also fosters a culture of continuous improvement, where insights from certification results are used to refine manufacturing processes, ultimately driving the evolution of their products to new levels of excellence.